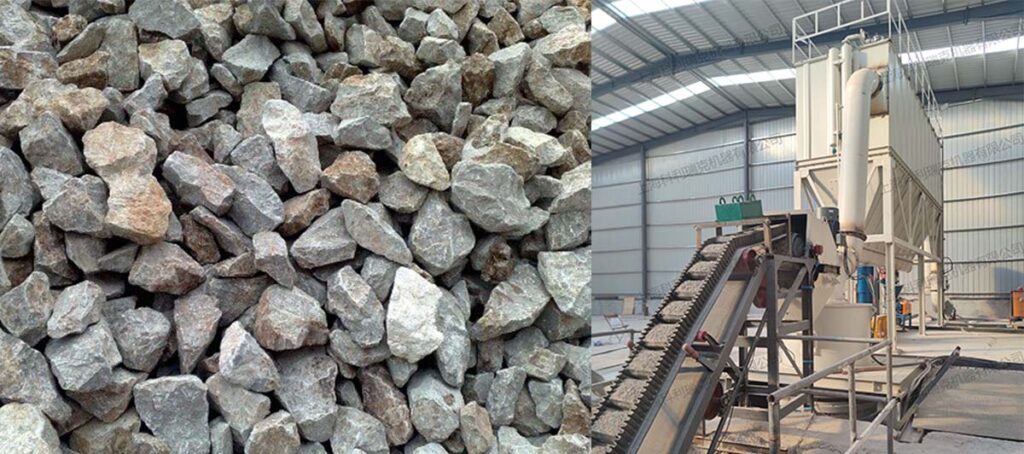

1. Raw Material Preparation

Crushed limestone (≤15 mm) is first broken down by a hammer crusher or jaw crusher to meet the feeding size requirement.

2. Feeding System

The crushed limestone is lifted by a bucket elevator into a storage hopper, then evenly and continuously fed into the HGM ultrafine grinding chamber via a vibrating feeder.

3. Grinding Process

Inside the mill, the main motor drives the grinding disc to rotate. Dozens of grinding rollers roll along the grinding ring under centrifugal force. The limestone is ground between the rollers and ring, passing through multiple layers (usually 3–4) to achieve ultra-fine powder.

4. Classification

A high-speed classifier (analyzer) separates the powder. Coarse particles return to the grinding chamber for further milling, while fine particles (up to 1000 mesh or ~13 μm) are carried by airflow into the next stage.

5. Collection

Qualified powder enters the cyclone collector and is discharged as final product through a rotary valve. A pulse dust collector ensures clean air emission and captures any residual fine dust.

6. Packaging

The collected 1000-mesh limestone powder is conveyed to a packaging machine for automatic bagging or bulk storage.

Share: